18 Floors in Wood: Student Residence in Vancouver

Photo: Pollux Chung /courtesy of Seagate Structures

In the forested western Canadian province of British Columbia, wood enjoys a long tradition as a building material. However, compared to conventional wood-frame construction techniques, modern wood building plays a subordinate role.

The residence was built within the framework of the Tall Wood Demonstration Initiative, which the Canadian government hopes will kickstart innovation. In 2013, Vancouver’s University of British Columbia announced a tendering procedure for a student residence constructed using wood building processes. The winning team, Acton Ostry Architects of Vancouver and Hermann Kaufmann Architekten of Schwarzach, presented their design for a modular wooden structure that would enable fast, simple building techniques.

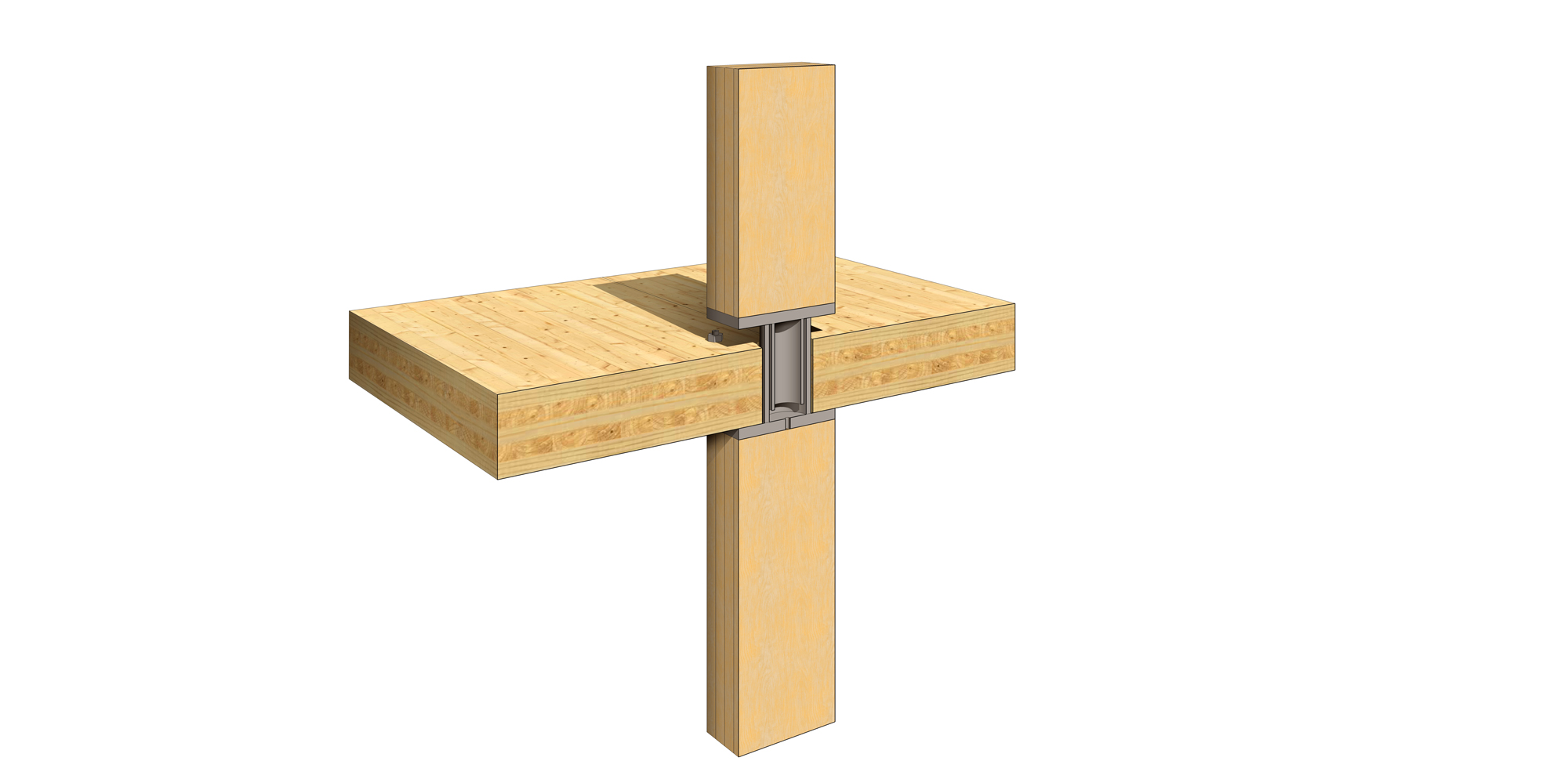

The new building consists of only two constructive elements: 26 x 25 cm glulam supports arranged in a grid measuring 2.85 x 4.00 m, and 16.9-cm-thick ceiling slabs of cross-laminated timber. Standardized steel plug-in connectors ensure vertical load transmission from support to support and hold the ceiling slabs in place.

The 18-floor wooden construction took only nine weeks to build. The ceiling slabs are arranged longitudinally with offset joints without any beams to get in the way. These are shear-resistant and connected with sunken three-layer slabs. This creates a statically useful plate that takes horizontal forces such as wind pressure and channels them into the two bracing reinforced-concrete stairwells. The plate effect is also beneficial because Vancouver is at high risk for earthquakes.

For both economic and practical reasons, the wood supports and ceilings were clad with drywall; the floors were covered with a screed. This made smaller wooden cross-sections and lower-quality wood surfaces possible. Moreover, the drywall facilitates the frequent renovation work required in student residences. The role-model function of the high-rise can be seen in the building costs, which were kept within budget, and the building time, which was four months less than it would have been with a concrete structure. The intelligent, economical and sustainable wooden building speaks for itself.

The Atlas Mehrgeschossiger Holzbau [Atlas of Multistorey Wooden Buildings], published by Detail, presents an extensive documentation of this project.

The residence was built within the framework of the Tall Wood Demonstration Initiative, which the Canadian government hopes will kickstart innovation. In 2013, Vancouver’s University of British Columbia announced a tendering procedure for a student residence constructed using wood building processes. The winning team, Acton Ostry Architects of Vancouver and Hermann Kaufmann Architekten of Schwarzach, presented their design for a modular wooden structure that would enable fast, simple building techniques.

The new building consists of only two constructive elements: 26 x 25 cm glulam supports arranged in a grid measuring 2.85 x 4.00 m, and 16.9-cm-thick ceiling slabs of cross-laminated timber. Standardized steel plug-in connectors ensure vertical load transmission from support to support and hold the ceiling slabs in place.

The 18-floor wooden construction took only nine weeks to build. The ceiling slabs are arranged longitudinally with offset joints without any beams to get in the way. These are shear-resistant and connected with sunken three-layer slabs. This creates a statically useful plate that takes horizontal forces such as wind pressure and channels them into the two bracing reinforced-concrete stairwells. The plate effect is also beneficial because Vancouver is at high risk for earthquakes.

For both economic and practical reasons, the wood supports and ceilings were clad with drywall; the floors were covered with a screed. This made smaller wooden cross-sections and lower-quality wood surfaces possible. Moreover, the drywall facilitates the frequent renovation work required in student residences. The role-model function of the high-rise can be seen in the building costs, which were kept within budget, and the building time, which was four months less than it would have been with a concrete structure. The intelligent, economical and sustainable wooden building speaks for itself.

The Atlas Mehrgeschossiger Holzbau [Atlas of Multistorey Wooden Buildings], published by Detail, presents an extensive documentation of this project.