25 square metres of independence: The Koda micro-home by Kodasema

Photo: Tõnu Tunnel

Pre-fabricated box frame-type units can take on many forms, ranging from the mobile homes of the USA. to the modular refugee accommodation erected in Germany over the past months. But such units are seldom built of concrete since the massive construction material is regarded as too inflexible and too heavy. Rather, the future seemed to lie in timber construction.

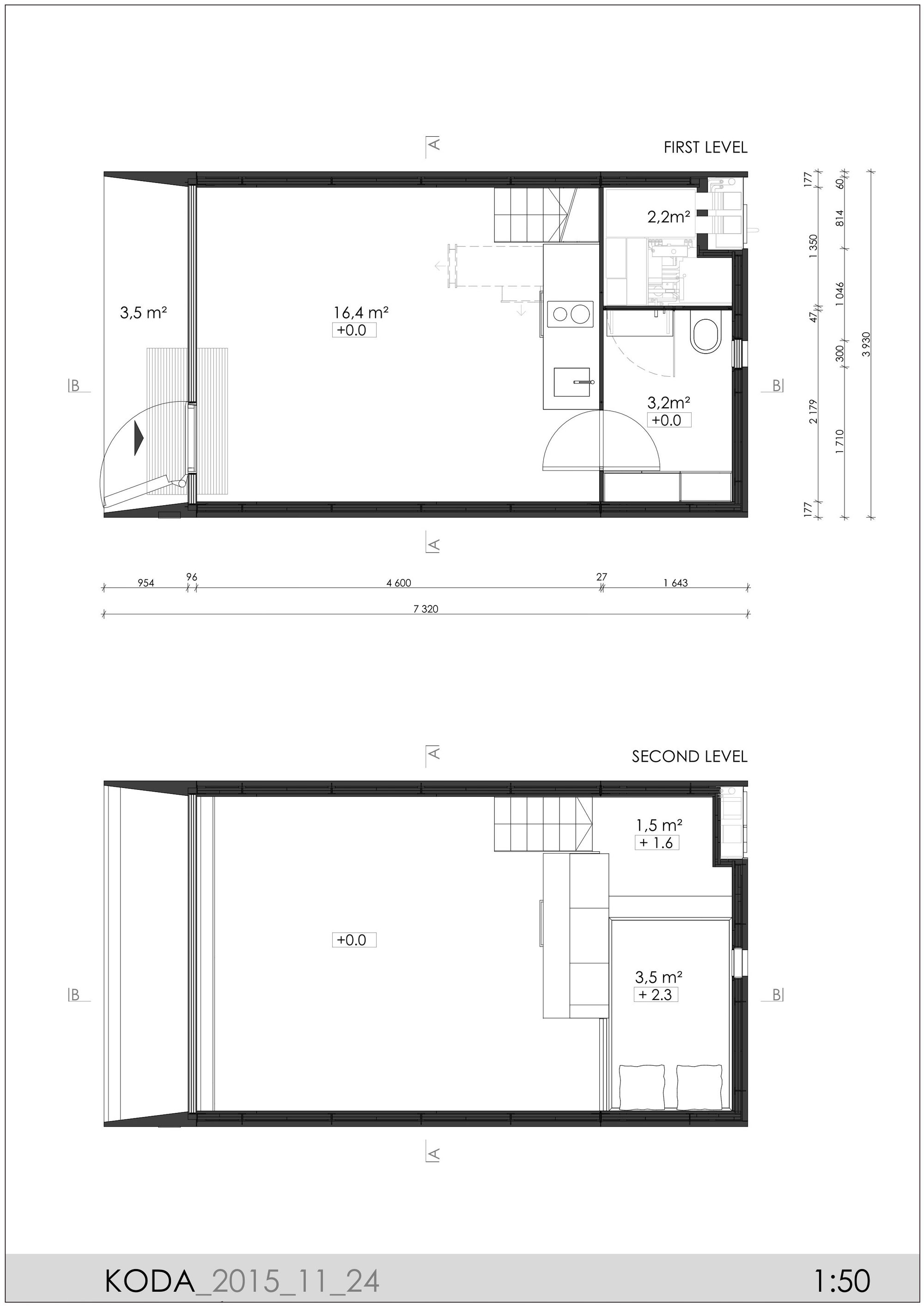

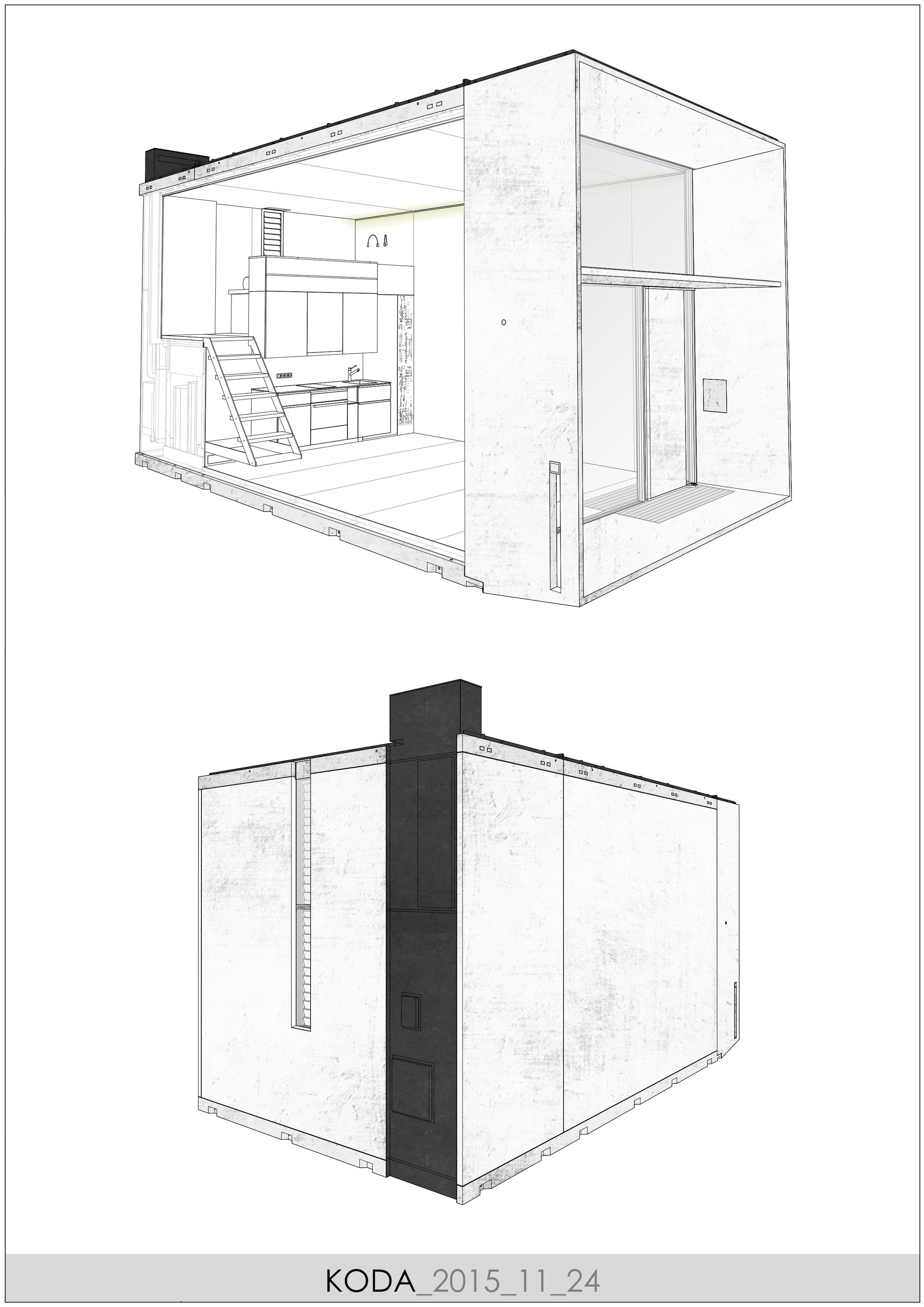

The Koda house prototype by Kodasema, an Estonian architectural practice, shows that a combination of wood and concrete can cut a good figure and offer functional advantages at the same time. The modular structure with a 25.8-square-metre footprint will be entering series production this year, ready-fitted to provide two people a home, or configured to act as a group office for 3 to 4 employees or as a mini classroom for 12 to 16 school students.

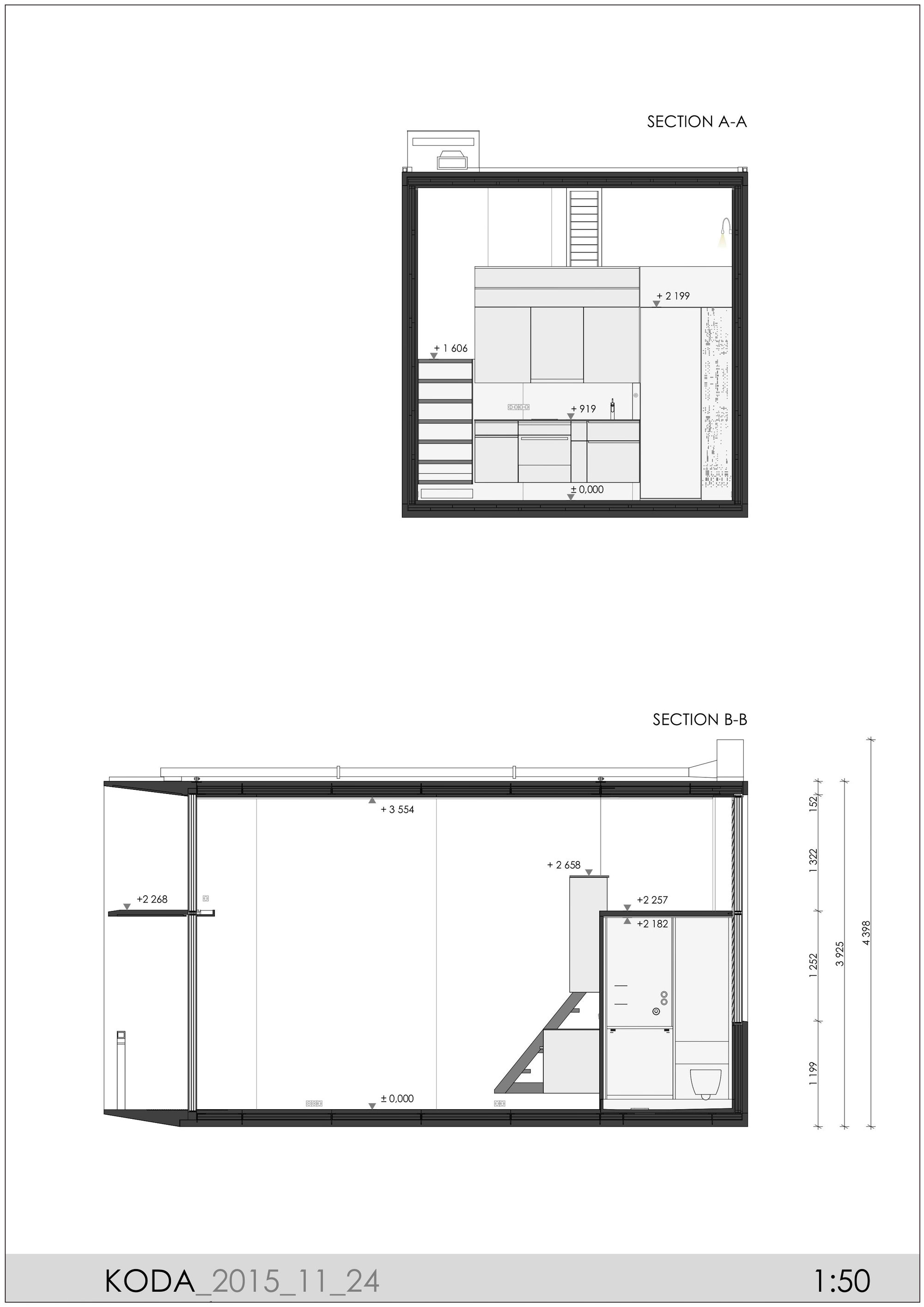

At first glance, the cubic volume seems somewhat insubstantial, but those outer walls measuring a mere 178 millimetres thick involve cutting-edge materials technology. This is to be seen in the cross-laminated panels as well as the vacuum insulation panels and pre-cast fibre cement panels, both 60 millimetres thick, that form the walls from the inside to the outside. Having been cast over old yacht sails, the cement panels show the seams, creases and stitching that have literally made their mark on the material.

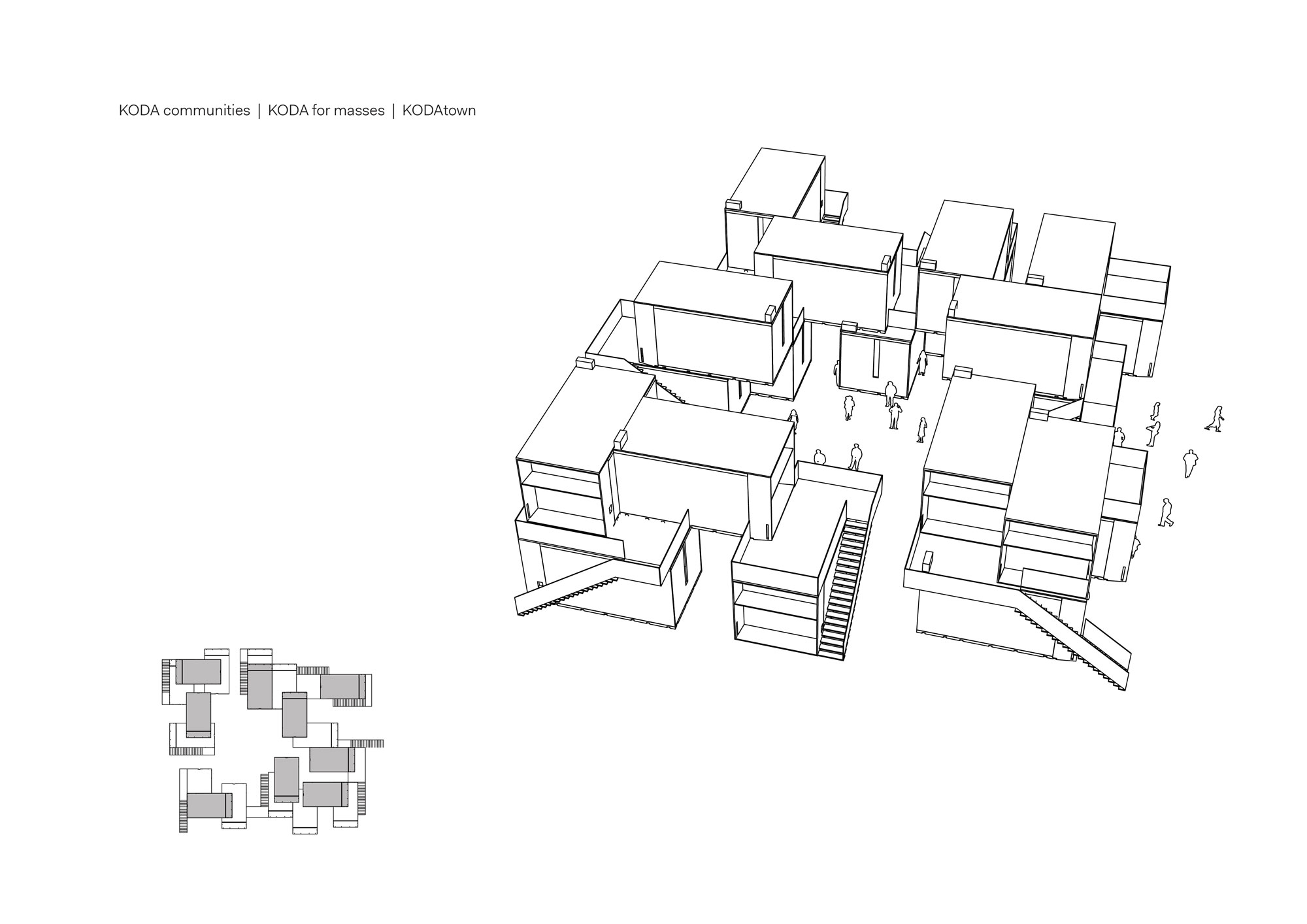

At an outer width of 3.93 metres the modules can be transported on a flat-bed truck to the building site, but also dismantled into handier component parts within a mere four to seven hours. On principle the Koda house can therefore be taken apart and set up again elsewhere, thus also lending itself to temporary use at sites awaiting development. As the architects point out, large town planning projects can take years from the planning start to the actual ground-breaking ceremony and the Koda modules could serve as student accommodation, school pavilions or interim offices during this time.

The architects have not stinted on modern energy-efficiency technology in their modular building: the outer walls come with a U value of 0.1 W/m2, while the four-ply glass at the front of the structure delivers a U value of 0.33 W/m2. Standard fittings include an enthalpy heat exchanger to take care of aeration and ventilation, and a reversible heat pump for heating and cooling. Even the drain pipe is fitted with a heat exchanger to enable the heat remaining from shower water to be used to heat drinking water. Solar modules on the roof are to make the house energy-neutral on an annual basis but the building will need a mains connection as it does not feature battery storage.

The projecting side walls, the roof and the sun baffle at the height of the door lintel are to protect the front of the building from too much sun in summer. At the rear part of the container structure, the architects have inserted a bedroom loft with a small bathroom fronted by a fully-equipped kitchen below it, making the Koda a »plug-and-play« building – an important aspect for clients in a hurry.

The Koda house prototype by Kodasema, an Estonian architectural practice, shows that a combination of wood and concrete can cut a good figure and offer functional advantages at the same time. The modular structure with a 25.8-square-metre footprint will be entering series production this year, ready-fitted to provide two people a home, or configured to act as a group office for 3 to 4 employees or as a mini classroom for 12 to 16 school students.

At first glance, the cubic volume seems somewhat insubstantial, but those outer walls measuring a mere 178 millimetres thick involve cutting-edge materials technology. This is to be seen in the cross-laminated panels as well as the vacuum insulation panels and pre-cast fibre cement panels, both 60 millimetres thick, that form the walls from the inside to the outside. Having been cast over old yacht sails, the cement panels show the seams, creases and stitching that have literally made their mark on the material.

At an outer width of 3.93 metres the modules can be transported on a flat-bed truck to the building site, but also dismantled into handier component parts within a mere four to seven hours. On principle the Koda house can therefore be taken apart and set up again elsewhere, thus also lending itself to temporary use at sites awaiting development. As the architects point out, large town planning projects can take years from the planning start to the actual ground-breaking ceremony and the Koda modules could serve as student accommodation, school pavilions or interim offices during this time.

The architects have not stinted on modern energy-efficiency technology in their modular building: the outer walls come with a U value of 0.1 W/m2, while the four-ply glass at the front of the structure delivers a U value of 0.33 W/m2. Standard fittings include an enthalpy heat exchanger to take care of aeration and ventilation, and a reversible heat pump for heating and cooling. Even the drain pipe is fitted with a heat exchanger to enable the heat remaining from shower water to be used to heat drinking water. Solar modules on the roof are to make the house energy-neutral on an annual basis but the building will need a mains connection as it does not feature battery storage.

The projecting side walls, the roof and the sun baffle at the height of the door lintel are to protect the front of the building from too much sun in summer. At the rear part of the container structure, the architects have inserted a bedroom loft with a small bathroom fronted by a fully-equipped kitchen below it, making the Koda a »plug-and-play« building – an important aspect for clients in a hurry.

Further information:

Costs: Ca. 120.000 Euro

Area: 25.8 m²

Weight: 28 Tonnen

Costs: Ca. 120.000 Euro

Area: 25.8 m²

Weight: 28 Tonnen