Leafbed - Made in Cardboard

Foto: Jens Kirchner, Düsseldorf

The Leafbed, a corrugated cardboard bed designed for temporary and emergency shelter situations was on display at this month's Paris design week 2011.

The concern of the French social business Leaf Supply and NOCC, a Paris-based industrial design studio,

was to design a bed that was simple, cost-efficient, disposable and adaptable to any situation in order to allow for its use in disaster regions worldwide.

Consequently their choice of material was double-layered corrugated cardboard, which is structurally strong, inexpensive to produce and easy to handle.

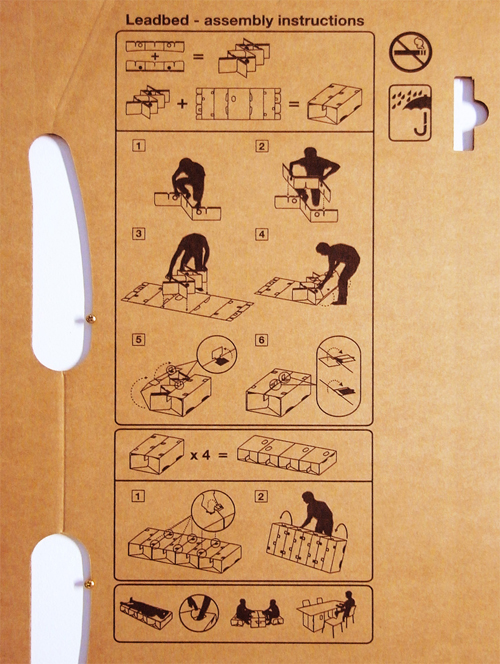

The Leafbed is assembled from

four identical modules of double-layered corrugate cardboard that have a simple inner-structure and outer-shell configuration.

The modules can also be used as

other pieces of indoor furniture such as small table comprised of two modules or as stools by making use of one module only.

Each module has been tested to resist loads of up to 300 kg (661 lbs) in environments with

75% humidity levels and 30°C (86° F) temperatures.

The double-layered corrugate cardboard is the industry's standard

that is found all over the world.

Therefore the Leafbed can be produced worldwide locally and is therefore quickly available in large quantities while production is kept with a small carbon footprint as transportation distance is little.

A partnership between Leaf Supply and the cardboard manufacturers

Smurfit Kappa Group and Rossmann could allow that Leafbeds are produced locally in every country of Europe, Latin America and

Western Africa (35 countries and 380 plants).

In general the beds are produced in the group's factory closest to a disaster region to shorten shortening the delays of supplying help to people in need.

Until today over 300 Leafbeds have been deployed in various areas such as for example in Niger.