Environmentally-friendly steel for CO2 reduction

Today, the sustainable use of raw materials and their environmentally-friendly processing is becoming increasingly important. Climate change and resource scarcity are real issues and call for a paradigm shift in industry. At the same time, this needs to be reconciled with the needs of society. In Germany, the construction industry is flourishing, which at the same time means a high demand for certain materials. This makes it all the more important for companies to optimise their production processes to such an extent that they can manufacture their products in the most environmentally-friendly and resource-conserving way possible. As part of this, the Deutsche Bundesstiftung Umwelt (DBU) has funded a research project focusing on the development of a new steel grade that is both environmentally-friendly in its production and resource-saving in its composition.

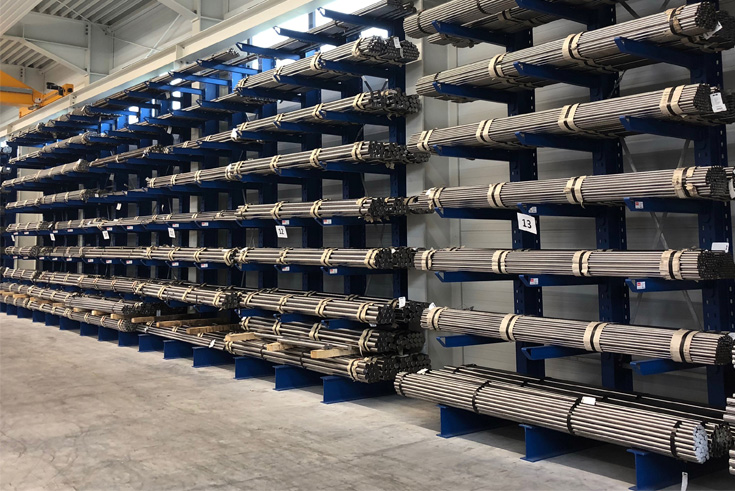

Energy-intensive production of steel

Steel production involves numerous machining processes. The current state of the art is to alloy steel with a certain amount of lead to make it easier to shape. However, lead is a heavy metal and is therefore considered to be very harmful to the environment and health. After the steel has been shaped, it must be thermally hardened. This generally results in it becoming somewhat distorted, which is why it has to be reworked in a further step. This post-processing generates waste in the form of chips. These material losses must therefore be planned for in advance. In addition, post-processing and hardening processes are very energy-intensive and are also responsible for enormous greenhouse gas emissions. Around 53,000 tons of carbon dioxide are emitted annually during the hardening process. This corresponds approximately to the emissions of a small town with about 4,500 inhabitants. For more than two years, a team from econsteel researched the development of a new steel grade that does not require the addition of lead. A new technical hardening process also makes it possible to reduce the greenhouse gases produced in the hardening process by almost 99%. In contrast to conventional steel types, the surface of the developed steel grade can be hardened through a purely mechanical process called roller burnishing to such an extent that conventional hardening processes can be dispensed with. This enables new efficient applications of the highest quality. In addition, the development of this new class of steel also means that the waste previously caused by distortion is eliminated.

Large-scale production?

The research results could be ground-breaking for the industry, but many other aspects would have to be taken into account for broad application to be possible. Currently the new steel grade is still unique and exclusive on the market. If the steel is to be suitable for mass production, everyone from material suppliers to automobile manufacturers will need to adapt their production processes, since components are diverse and complex. The aim is to find solutions that are desirable for all concerned. In a next step, therefore, the mechanical hardening process will be further developed, with the DBU recently approving a new grant to this end. It is a positive development that institutions and companies are increasingly focusing on the environmentally-friendly manufacture of products. Should in the wake of climate change a CO2 tax be introduced, the spotlight would be shone even more strongly on developments such as the combination of a new steel material and mechanical hardening, which can substantially reduce the amount of greenhouse gases produced compared to the previous production process.