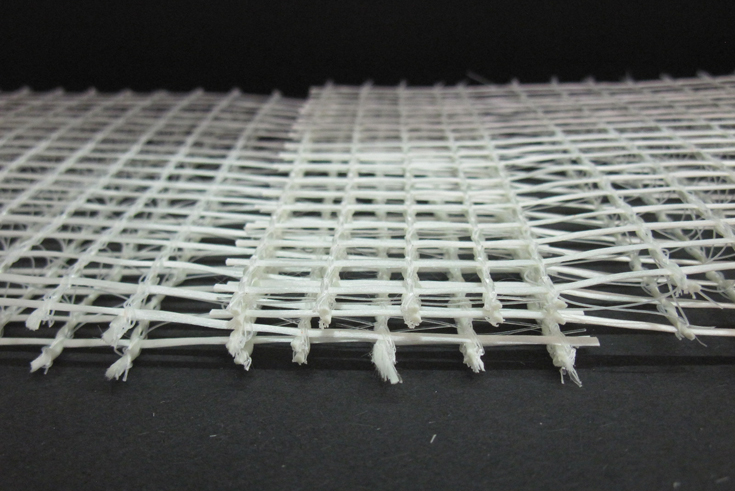

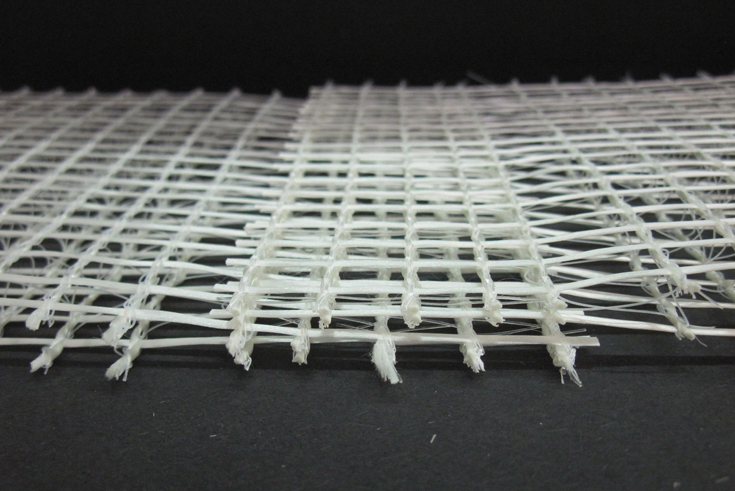

3D high-performance grid made of AR glass or carbon

Foto: Hersteller

The great advantage of textile concrete is its corrosion resistance and high strength. This enables positioning close to the surface and the production of particularly thin and light precast concrete parts or reinforcements. One problem so far has been the connection of 3D biaxial reinforcement grids. This problem has now been solved by V. FRAAS Solutions in Textile GmbH.

3D textile reinforcements for concrete are three-dimensional, biaxial spacer fabrics in which two biaxial grids made of alkali-resistant AR glass or carbon are connected to each other in a compression-resistant manner using pile yarns. The distance of the grids and density of the pile yarns are variable. Up to now, 3D biaxial grids have been joined butt to butt with a 2D reinforcement at the top and bottom as an overlap. This resulted in a disadvantageous thickening in the length of the overlaps as well as additional material costs due to the 2D reinforcements used at the joints. The high-performance grids from V. Fraas Solutions in Textile, on the other hand, are narrower at the right and left edges, where the 3D textiles converge. Thus, the 3D structures can be continued endlessly in rolls. The combination of the reinforcement layers on top of each other can be done individually according to customer requirements with regard to the length of the tapered overlaps.

The 3D textile reinforcements made of carbon were used in a new building for Alphabeton AG in Switzerland and in the facade of the Institute for Building Materials Science at the TU Dresden. Additional references include the facade of Arnhem railway station, the reinforcement of a listed reinforced concrete barrel-roof in Zwickau, and the renovation of a supporting structure in Schweinfurt.

www.solutions-in-textile.com