Bioreactor systems integrated in the façade – University of Applied Sciences Augsburg

Foto: HS Augsburg

How and where will food and renewable resources be produced for projected 10 billion people in 2050? How can we avoid the plate-tank-trough problem? And how do future agricultural land and cities look like? An interdisciplinary team in the BMBF-funded joint research project “Next Generation Biofilm – the Rose of Jericho of Biotechnology” is developing innovations by finding solutions to these challenges.

The researchers of the Universities of Applied Sciences in Kaiserslautern, Trier, Augsburg and of the Technical University Kaiserslautern are geared towards the development of new production techniques and processes of terrestrial microorganisms that do not live in water, but on land. For this purpose, a completely new platform technology is being developed which uses energy- and resource-efficient process technologies and implements a specific emerse, i.e. air-guided, production environment for terrestrial microorganisms. Integration in the façade offers various synergy effects that can have a positive effect on energy consumption of the reactor operation and building operation.

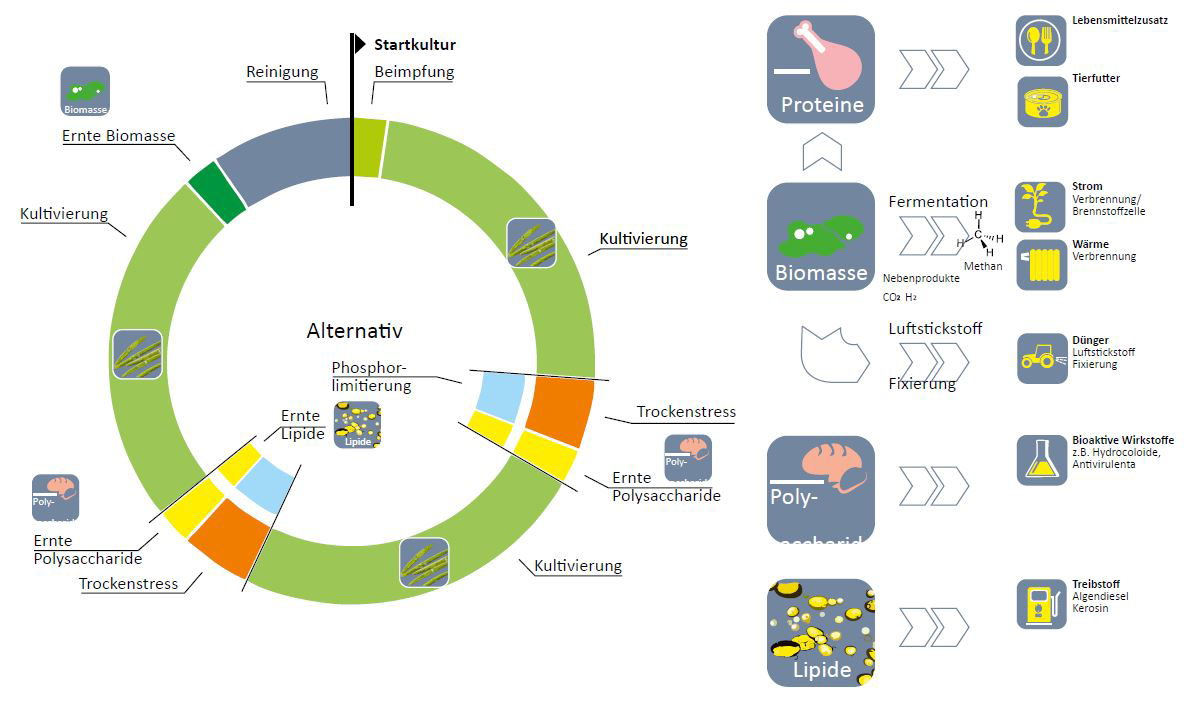

Possible end products include:

- Production of renewable biopolymers, dyes & fine chemicals

- Food and animal feed

- Energy carriers

- Biological fertilizers

First steps toward an energy-neutral algae bioreactor:

- Interdisciplinary BMBF-funded joint research project (2015-17: 1.2M €)

- Proof-of-concept: industry-oriented prototype

hs-augsburg.de

The researchers of the Universities of Applied Sciences in Kaiserslautern, Trier, Augsburg and of the Technical University Kaiserslautern are geared towards the development of new production techniques and processes of terrestrial microorganisms that do not live in water, but on land. For this purpose, a completely new platform technology is being developed which uses energy- and resource-efficient process technologies and implements a specific emerse, i.e. air-guided, production environment for terrestrial microorganisms. Integration in the façade offers various synergy effects that can have a positive effect on energy consumption of the reactor operation and building operation.

Possible end products include:

- Production of renewable biopolymers, dyes & fine chemicals

- Food and animal feed

- Energy carriers

- Biological fertilizers

First steps toward an energy-neutral algae bioreactor:

- Interdisciplinary BMBF-funded joint research project (2015-17: 1.2M €)

- Proof-of-concept: industry-oriented prototype

hs-augsburg.de