Clear Sign: a Plus for the Future

The German pavilion on the occasion of Expo 1967 in Montreal wrote architectural history. In its time one of the most beautiful and efficient buildings at the World Fair, it still sets standards today with regard to esthetics, engineering art and innovative strength in contemporary architecture. Frei Otto’s prototype structure, which predated the Expo pavilion, is still standing in the grounds of the University of Stuttgart-Vaihingen. It is a place laden with history which radiates an aura of sublime and timeless elegance from every fiber, in every recess.

Even after more than 40 years it has lost nothing of its structural quality. Today it houses the Institut für Leichtbau Entwerfen und Konstruieren (ILEK) [Institute for Design and Construction of Lightweight Structures] under the leadership of Prof. Werner Sobek. The prototype structure was the worthy ending to an informative day within the framework of the second symposium of the series of events organized by DETAIL research and the research initiative Zukunft Bau [Future Structures].

The guests met here in the evening for a “get together”. And here the circle came together to discuss the theme of the day. In the preceding five papers with the focus “energy-efficient construction” experts in the most diverse subject areas showed that the concept of energy efficiency is not just flowery language, and that sustainable architecture is brought about above all through innovation, esthetics and a holistic consideration of energy.

Even after more than 40 years it has lost nothing of its structural quality. Today it houses the Institut für Leichtbau Entwerfen und Konstruieren (ILEK) [Institute for Design and Construction of Lightweight Structures] under the leadership of Prof. Werner Sobek. The prototype structure was the worthy ending to an informative day within the framework of the second symposium of the series of events organized by DETAIL research and the research initiative Zukunft Bau [Future Structures].

The guests met here in the evening for a “get together”. And here the circle came together to discuss the theme of the day. In the preceding five papers with the focus “energy-efficient construction” experts in the most diverse subject areas showed that the concept of energy efficiency is not just flowery language, and that sustainable architecture is brought about above all through innovation, esthetics and a holistic consideration of energy.

Faraneh Farnoudi from Hild und K Architekten [Hild and K Architects] in Munich sees above all the climatic changes around the globe and the resulting increase in energy demands on architecture as one of the fundamental mainsprings of her creativity. Hild und K frequently work with WDV systems (WDVS) [thermal installation composite systems] which, although a cost-effective solution, are thoroughly contested within the architect community: beside the oft criticized use of fossil fuels in production, it is an unenthusiastic approach to the system that in many places is reflected in dull facades. Faraneh Farnoudi pointed out in her talk that there is indeed a highly creative, as well as energy-related potential in WDVS. “Creativity is the mainspring of our work, we want to find poetry in places where not everyone looks. This includes that the function of the system is visible – within the form, the façade.” This is an absolute success in the projects shown in Stuttgart.

As an example, the Hotel Louis in Munich abstracts the classical décor notion and is archetypal for Hild und K’s handling of its continuance. The conscious decision for a WDVS with its expressive and individual relief of the façade demonstrates that even in historically-formed surroundings, as is the case at the daily food market in Munich, the system is assigned an esthetic and economical significance.

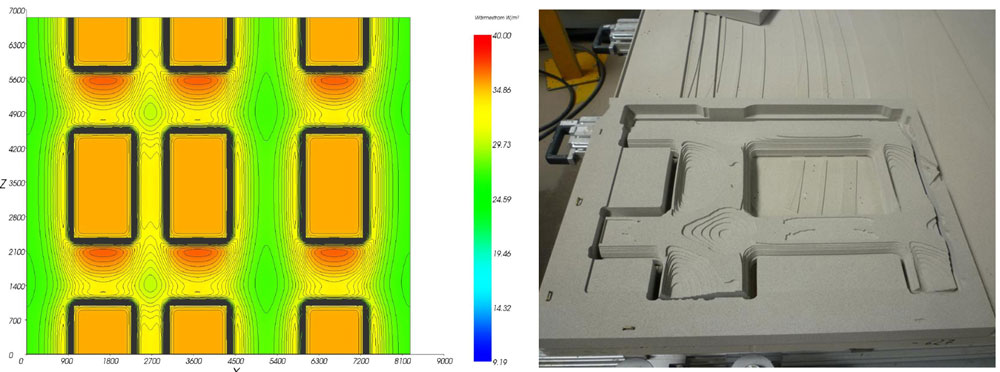

Faraneh Farnoudi presented a current research project that goes still one step further: for the energy-related improved efficiency of an existing façade the creative quality goes hand in hand with the energy-related requirements. By reference to the isobars (the thermal flow within the façade section of the building) that have been made visible, Faraneh Farnoudi illustrated where the necessary insulation material thickness could be minimized. Therefore the insulation material is applied where it is required and in the process is only carried out to the extent that it is demanded by the thermal flow from the inside to the outside. This is no technological pie in the sky.

The insulation boards are pre-milled and then installed in the location on the façade determined by calculations in advance. The result is a shifting façade image which, despite energy-related indices as the basis of calculation, possesses a high esthetic appeal. “Insulate more attractively” paper (German) to download as pdf

As an example, the Hotel Louis in Munich abstracts the classical décor notion and is archetypal for Hild und K’s handling of its continuance. The conscious decision for a WDVS with its expressive and individual relief of the façade demonstrates that even in historically-formed surroundings, as is the case at the daily food market in Munich, the system is assigned an esthetic and economical significance.

Faraneh Farnoudi presented a current research project that goes still one step further: for the energy-related improved efficiency of an existing façade the creative quality goes hand in hand with the energy-related requirements. By reference to the isobars (the thermal flow within the façade section of the building) that have been made visible, Faraneh Farnoudi illustrated where the necessary insulation material thickness could be minimized. Therefore the insulation material is applied where it is required and in the process is only carried out to the extent that it is demanded by the thermal flow from the inside to the outside. This is no technological pie in the sky.

The insulation boards are pre-milled and then installed in the location on the façade determined by calculations in advance. The result is a shifting façade image which, despite energy-related indices as the basis of calculation, possesses a high esthetic appeal. “Insulate more attractively” paper (German) to download as pdf

A further, important aspect of the use of WDVS, in addition to the energy-related economic considerations, is also the satisfaction of the user – and this, ideally not for one or two years but as proven through long-term monitoring. Roland Streng, applications engineer and product manager with BASF, provides interesting insights on this. The Brunck quarter of Ludwigshafen, a residential area of the BASF subsidiary Luwoge, built in the 1930’s, underwent a comprehensive, energy-related refurbishment in 2001. The insulating material “neopor” was used. Added to this was that, in the middle of the 1990’s the Brunck quarter was a social hot spot and, apart from the necessary rebuilding after the second world war, no comprehensive refurbishment ever took place. Therefore, comprehensive repair work, including the facades, was urgently required.

Twelve years after the refurbishment a review was due to be carried out. In 2013 BASF initiated an occupier survey through the Hildesheim/Holzminden/Göttingen College with the specialist organization Trenscouting Hildesheim. The result showed that between 80% and 90% of today’s residents were satisfied or very satisfied with the residential area.

Added to this was a consideration of the topics material fatigue, amortization and CO2 saving over long-term operation carried out by the independent test institutes. From this it could be demonstrated that no material fatigue had taken place. Damages were shown to be related to processing defects (armoring carried out in the wrong level, sealing omitted). A further, astounding effect: due to the good energy-related indices the amortization of the energy-related refurbishments is now 15 years and not, as previously calculated, 30 years (referred to the so-called three-liter house, for a standard refurbishment even less than this). In sum, the refurbishment of the residential area led to a CO2 saving of 2,300 metric tons over the last twelve years.

Indeed the forward view was also important to Roland Streng: In the European project Eurhonet, the “European Housing Network”, BASF is working with the French architects Nicolas Michelin and Luwoge on an apartment building in the passive-house style developed as a basic type to be modified and offered on the European market. The first of these houses is currently being built in Darmstadt and will be completed in the early summer of 2014 on the basis of construction products currently available. Thus, it is not a pure research project but rather a contribution to the current architectural discourse. Paper “Resource efficiency through plastics in construction” (German) to download as pdf

The trend setting use of product solutions available at present is also a declared objective for the project of Prof. Jörg Hildebrand (Bauhaus University Weimar) sponsored by the Bundesministerium [Federal Ministry]. His key focus is hybrid elements in the façade. High quality systems such as vacuum-insulating glass (VIG) and vacuum-insulating panels (VIP) are state-of-the-art. However, the connection of individual systems into a hybrid, the glass-plastic sandwich elements and the resulting increase in performance are part of his research in Weimar. Above all, consideration of the advantages and disadvantages within the composition of the composite construction was the subject of his paper.

An essential point here is the permanent connection of the individual components and the diffusion resistance of the edge composite of the VIG elements: The bonding must guarantee a high degree of gas-tightness. In addition there is the consideration of the total energy passage in the filling of the system components with different filling media. Likewise, specific, static requirements are to be observed. Thus, the selective failure of the external glass level does indeed signify the partial loss of the insulation function, however, not the static failure of the complete composite construction. It does not, therefore, need to be replaced immediately. Paper “Glass hybrid elements” (German) to download as pdf

Twelve years after the refurbishment a review was due to be carried out. In 2013 BASF initiated an occupier survey through the Hildesheim/Holzminden/Göttingen College with the specialist organization Trenscouting Hildesheim. The result showed that between 80% and 90% of today’s residents were satisfied or very satisfied with the residential area.

Added to this was a consideration of the topics material fatigue, amortization and CO2 saving over long-term operation carried out by the independent test institutes. From this it could be demonstrated that no material fatigue had taken place. Damages were shown to be related to processing defects (armoring carried out in the wrong level, sealing omitted). A further, astounding effect: due to the good energy-related indices the amortization of the energy-related refurbishments is now 15 years and not, as previously calculated, 30 years (referred to the so-called three-liter house, for a standard refurbishment even less than this). In sum, the refurbishment of the residential area led to a CO2 saving of 2,300 metric tons over the last twelve years.

Indeed the forward view was also important to Roland Streng: In the European project Eurhonet, the “European Housing Network”, BASF is working with the French architects Nicolas Michelin and Luwoge on an apartment building in the passive-house style developed as a basic type to be modified and offered on the European market. The first of these houses is currently being built in Darmstadt and will be completed in the early summer of 2014 on the basis of construction products currently available. Thus, it is not a pure research project but rather a contribution to the current architectural discourse. Paper “Resource efficiency through plastics in construction” (German) to download as pdf

The trend setting use of product solutions available at present is also a declared objective for the project of Prof. Jörg Hildebrand (Bauhaus University Weimar) sponsored by the Bundesministerium [Federal Ministry]. His key focus is hybrid elements in the façade. High quality systems such as vacuum-insulating glass (VIG) and vacuum-insulating panels (VIP) are state-of-the-art. However, the connection of individual systems into a hybrid, the glass-plastic sandwich elements and the resulting increase in performance are part of his research in Weimar. Above all, consideration of the advantages and disadvantages within the composition of the composite construction was the subject of his paper.

An essential point here is the permanent connection of the individual components and the diffusion resistance of the edge composite of the VIG elements: The bonding must guarantee a high degree of gas-tightness. In addition there is the consideration of the total energy passage in the filling of the system components with different filling media. Likewise, specific, static requirements are to be observed. Thus, the selective failure of the external glass level does indeed signify the partial loss of the insulation function, however, not the static failure of the complete composite construction. It does not, therefore, need to be replaced immediately. Paper “Glass hybrid elements” (German) to download as pdf

The focus of the project on glass façade elements with fluid flow-through being researched by the chair of Prof. Thomas Auer at the TU Munich is the specific behavior of glass as façade system, and the specific characteristics when handling the material, through to a new application spectrum.

The project is led by Jochen Stopper at the TU Munich who presented it to over 70 interested guests in the lecture hall of Stuttgart University.

Fluid flow-through glass has been researched since 1953. However, only in recent years have results been documented that will make possible its widespread use in the façade sector. The fluid-glass principle can be briefly explained: colored fluid is injected between the individual glass levels that are provided with ingress and egress openings in the area of the bonded edge. The sheets are thereby darkened. In order to remove the discoloration, transparent fluid is flushed through so that the colored fluid is forced out again. This can be repeated again and again in closed circulation with the same result.

TU Munich is working on the project ongoing through 2017 with different fluids and is experimenting with their response characteristics and light transmission, together with the increased energy-related characteristics arising from this. Besides less daylight, a fluid-darkened sheet also permits less heat radiation in the space behind the façade. Thus, glass facades with fluid flow-through are ideal for use in high-rise buildings where it is not possible to work with externally-located shading.

According to Jochen Stopper early field trials in Dubai have progressed very positively. From the two identical test areas (5.0 x 3.5 x 3.0 m (L/W/H)) in Munich and Dubai the TU Munich researchers are promising the development of the first prototypes in the foreseeable future, which, even in climatic regions other than in Germany, will achieve good energy-related results. Indeed, the perfect fluid and the ideal system structure has not yet been found. Further work will be carried out on this, reports Jochen Stopper. Therefore, two further test containers are planned which will additionally provide, from 2016, new insights into the use of fluid-filled façade systems – also in the European sector. Paper “fluid glass” (German) to download as pdf

The project is led by Jochen Stopper at the TU Munich who presented it to over 70 interested guests in the lecture hall of Stuttgart University.

Fluid flow-through glass has been researched since 1953. However, only in recent years have results been documented that will make possible its widespread use in the façade sector. The fluid-glass principle can be briefly explained: colored fluid is injected between the individual glass levels that are provided with ingress and egress openings in the area of the bonded edge. The sheets are thereby darkened. In order to remove the discoloration, transparent fluid is flushed through so that the colored fluid is forced out again. This can be repeated again and again in closed circulation with the same result.

TU Munich is working on the project ongoing through 2017 with different fluids and is experimenting with their response characteristics and light transmission, together with the increased energy-related characteristics arising from this. Besides less daylight, a fluid-darkened sheet also permits less heat radiation in the space behind the façade. Thus, glass facades with fluid flow-through are ideal for use in high-rise buildings where it is not possible to work with externally-located shading.

According to Jochen Stopper early field trials in Dubai have progressed very positively. From the two identical test areas (5.0 x 3.5 x 3.0 m (L/W/H)) in Munich and Dubai the TU Munich researchers are promising the development of the first prototypes in the foreseeable future, which, even in climatic regions other than in Germany, will achieve good energy-related results. Indeed, the perfect fluid and the ideal system structure has not yet been found. Further work will be carried out on this, reports Jochen Stopper. Therefore, two further test containers are planned which will additionally provide, from 2016, new insights into the use of fluid-filled façade systems – also in the European sector. Paper “fluid glass” (German) to download as pdf

“If it is a case of using new materials and systems with no general approval, the architect finds himself having to offer an explanation. Then he can often only build his own house and grapple there with innovative new developments”. Prof. Frank Hülsmeier from the HTWK Leipzig has himself experimented with vacuum-insulated façade elements; His private house arose in lightweight steel and wood construction and vacuum insulated exterior shell with a high proportion of prefabrication. Certainly, for him, the future does not lie in renewable raw materials, as one might hypothesize from the use of wood in his residential house.Both the current growth in population as well as the strained foodstuffs situation (speculation with rape, maize, etc.) bring into focus for him the glass-fiber-reinforced cement (textile-reinforced concrete) and the vacuum-insulating panels (VIP). This he combines into a vacuum-insulating, façade element made from textile-reinforced concrete – likewise a sandwich construction as presented by Prof. Hildebrand, but with a total thickness of 11 cm with a U value of 0.12 W/m²K (without interruption, that is without joint) or 0.18 W/m²K (interrupted with joint). Despite the slender total height the element with a width of 1.50 m and a height of 3.00 m offers, thereby, the same power values as a passive-house façade element with a current structure of 44 cm.In the current stage of development fire protection remains a problem to be solved. The small amount of concrete covering leads to spalling during a fire test. At <B30 the required fire protection is not yet fulfilled. However, that is resolvable, says Frank Hülsmeier. Currently, attention is also on the fastening of the system panels and the leak-tightness of the joints which, according to new energy conservation regulations, have a direct influence on the complete façade component. At a price of about 490 €/m² the façade element is still very expensive. Nevertheless, Frank Hülsmeier sees an advantage above all in the small, sealing surfaces (between 10% and 15%): “It is precisely in the expensive inner-city locations that every square meter additionally available due to the low thickness of the system equates to ready cash. The market potential is absolutely there in regions such as, e.g. China. Added to this is that stockpiling is very easy to facilitate due to the low weight.”

Paper “Vacuum-insulated façade elements” (German) to download as pdf

The hosts in Stuttgart - the team around Prof. Werner Sobek from ILEK – insisted on holding the closing address for the event. As representative of the hosts, project manager Christian Bergmann reported on the “active-house principle”. With the help of the much-publicized efficiency house plus in Berlin he could substantiate that energy self-sufficiency is no longer a dream of the future and even more: the supply of self-generated power into the electricity network will soon allow every building to be converted to a plus-energy house.

According to his theory the complex networking of the intelligent-home components in the coming years will yield simple components which communicate with one another, and thus make the solutions more coherent. However, the role of the architect in public will continue to be decisive. The roundly propagated energy revolution must, in future, be reflected in the buildings and become anchored in society. Hereby, topics such as e-mobility or innovative traffic concepts play a very large role.

One example of how architecture, energy self-sufficiency and mobility could intertwine in future, is the project “B 10” presented by Christian Bergmann. The prototype is a constituent part of the national project ”Schaufenster Elektromobilität” [“Electro-mobility shop window”] sponsored by the Federal government. The temporary structure will be completed in May 2014 and is located on a plot of land in the area of the Weissenhof estate in Stuttgart. The cubic building is thus in the middle of archetypes of the modern guest stay. It is planned to stay there for one year on a ground area of 14 x 6 m and be occupied during this period. Comprehensive monitoring will facilitate calculation of its energy efficiency.

With this project Werner Sobek is pursuing three objectives: to apply and extend the knowledge gained in precursor projects (R128, R129, P12), to interconnect the built environment, e-mobility and power generation and provide a perspective on future living. Due to the high level of prefabrication (timber-frame construction) and the so-called “energy racks” (bundling the intelligent home) the construction of “B 10” will require one week.

Besides the story-high, vacuum-insulation glazing that uncovers extensive insights into the living space and living environment, the textile covering of the cladding is conspicuous. The energy-related concept provides for 200% of the required power to be generated by the building. The excess is transferred during the operating phase to the Le Corbusier house standing within view of the building where it should supply the exhibition and two e-mobiles with power. Paper “The principle of the active house” (German) to download as pdf

According to his theory the complex networking of the intelligent-home components in the coming years will yield simple components which communicate with one another, and thus make the solutions more coherent. However, the role of the architect in public will continue to be decisive. The roundly propagated energy revolution must, in future, be reflected in the buildings and become anchored in society. Hereby, topics such as e-mobility or innovative traffic concepts play a very large role.

One example of how architecture, energy self-sufficiency and mobility could intertwine in future, is the project “B 10” presented by Christian Bergmann. The prototype is a constituent part of the national project ”Schaufenster Elektromobilität” [“Electro-mobility shop window”] sponsored by the Federal government. The temporary structure will be completed in May 2014 and is located on a plot of land in the area of the Weissenhof estate in Stuttgart. The cubic building is thus in the middle of archetypes of the modern guest stay. It is planned to stay there for one year on a ground area of 14 x 6 m and be occupied during this period. Comprehensive monitoring will facilitate calculation of its energy efficiency.

With this project Werner Sobek is pursuing three objectives: to apply and extend the knowledge gained in precursor projects (R128, R129, P12), to interconnect the built environment, e-mobility and power generation and provide a perspective on future living. Due to the high level of prefabrication (timber-frame construction) and the so-called “energy racks” (bundling the intelligent home) the construction of “B 10” will require one week.

Besides the story-high, vacuum-insulation glazing that uncovers extensive insights into the living space and living environment, the textile covering of the cladding is conspicuous. The energy-related concept provides for 200% of the required power to be generated by the building. The excess is transferred during the operating phase to the Le Corbusier house standing within view of the building where it should supply the exhibition and two e-mobiles with power. Paper “The principle of the active house” (German) to download as pdf