Moholt Student Towers

Photo: MDH Arkitekter

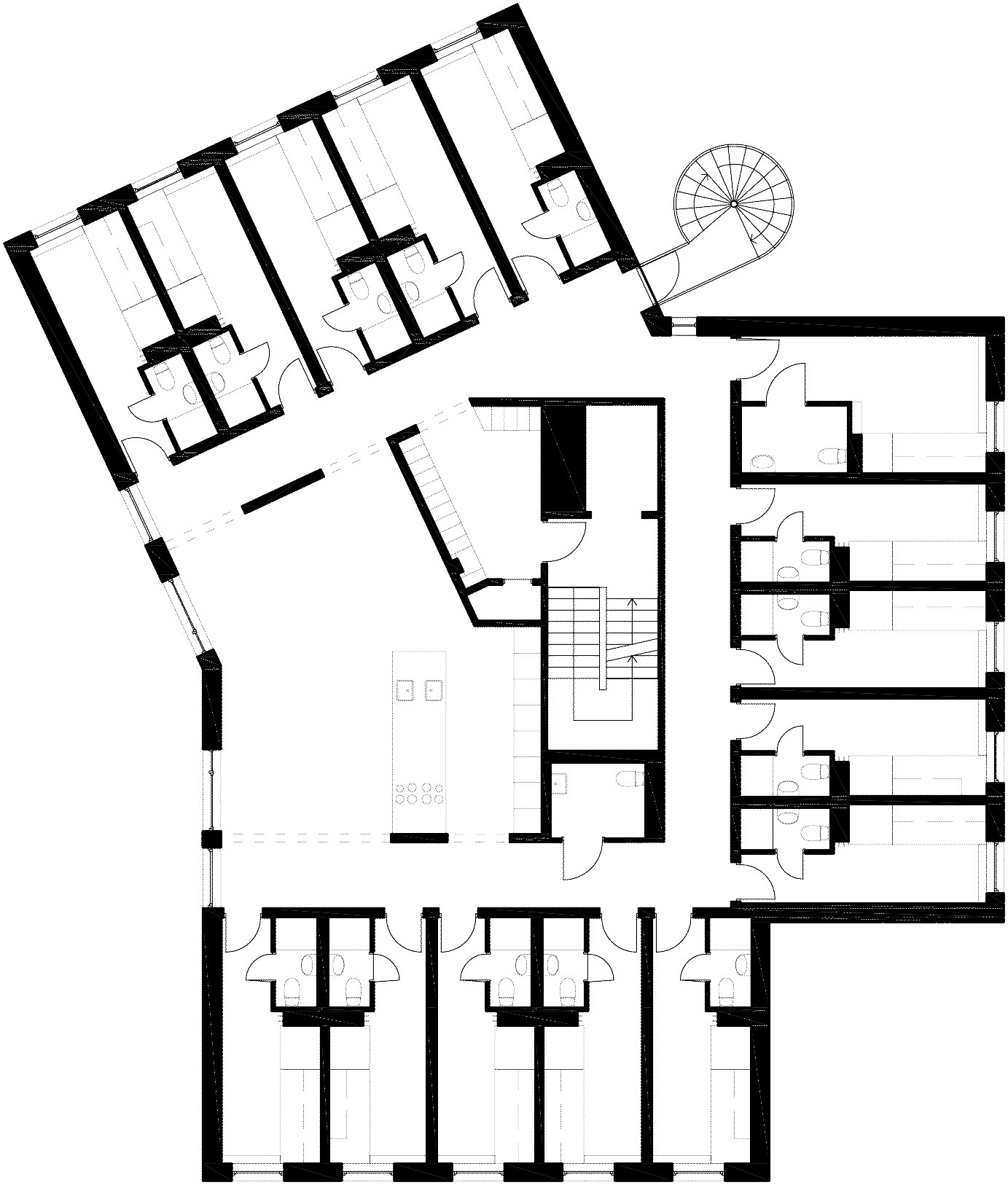

Originally the architects were intending to provide the housing towers with masonry infill walls within a reinforced concrete framework – a conventional means of construction oriented to the existing red brick buildings. However, the energy-efficiency concept for the student housing towers had to fulfil stringent requirements, with the result that the planners examined whether a wooden structure made up of cross-laminated timber (CLT) would satisfy these demands. In statical terms the relatively short spans in the towers and their y-shaped cross-section proved suitable for use of CLT. At the same time the massive wooden elements act as planar structural members, enabling them to withstand horizontal forces such as wind load, storey for storey. The architects also varied the geometry of the connections between the timber elements according to storey and load stress.

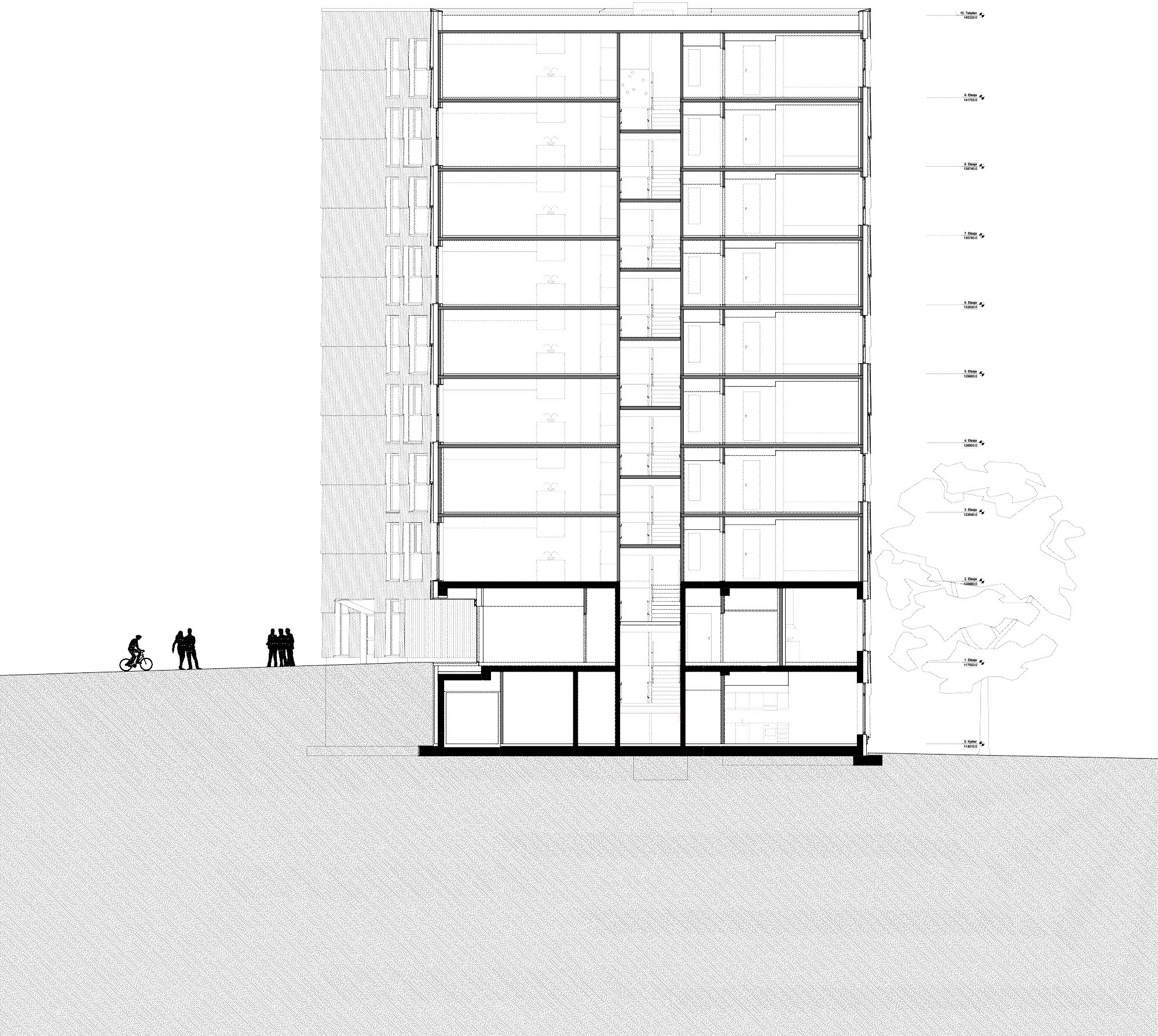

The nine-storey towers are all 28 metres high and feature ground floors and basements built in reinforced in-situ concrete. Pre-fabricated CLT elements form the supporting structure of the higher floors, and the same material has been used for the elevator shafts and staircases. Both outer and inner walls act as load-bearing elements, with the visible wooden surface of the latter determining the character of the interiors. Fire protection tests at a 1:1 scale helped derive reliable data on fire behaviour, necessary element dimensioning, burning rate and sprinkler capacity. Plasterboard panels incorporated into the individual ceilings and walls and also the screed and insulating material help fulfil fire safety and sound insulation requirements. A number of the load-bearing walls, such as the inner staircase shafts, have a transparent fire-proof coating.

The facades of the residential towers are clad in overlapping pinewood panels, which have been provided a coating based on organic substances to increase their durability but otherwise left untreated. The outer skin on the ground floor level has been additionally provided fire-retardant coating.

The housing towers were built according to the ultra-low-energy house standard, with use of cross-laminated timber reducing CO2 consumption by some 75 percent in comparison to conventional construction means. The buildings are heated and cooled with geothermal energy.

The nine-storey towers are all 28 metres high and feature ground floors and basements built in reinforced in-situ concrete. Pre-fabricated CLT elements form the supporting structure of the higher floors, and the same material has been used for the elevator shafts and staircases. Both outer and inner walls act as load-bearing elements, with the visible wooden surface of the latter determining the character of the interiors. Fire protection tests at a 1:1 scale helped derive reliable data on fire behaviour, necessary element dimensioning, burning rate and sprinkler capacity. Plasterboard panels incorporated into the individual ceilings and walls and also the screed and insulating material help fulfil fire safety and sound insulation requirements. A number of the load-bearing walls, such as the inner staircase shafts, have a transparent fire-proof coating.

The facades of the residential towers are clad in overlapping pinewood panels, which have been provided a coating based on organic substances to increase their durability but otherwise left untreated. The outer skin on the ground floor level has been additionally provided fire-retardant coating.

The housing towers were built according to the ultra-low-energy house standard, with use of cross-laminated timber reducing CO2 consumption by some 75 percent in comparison to conventional construction means. The buildings are heated and cooled with geothermal energy.