Stacked modules: Student housing near Barcelona

Photograph: Adrià Goula, Barcelona

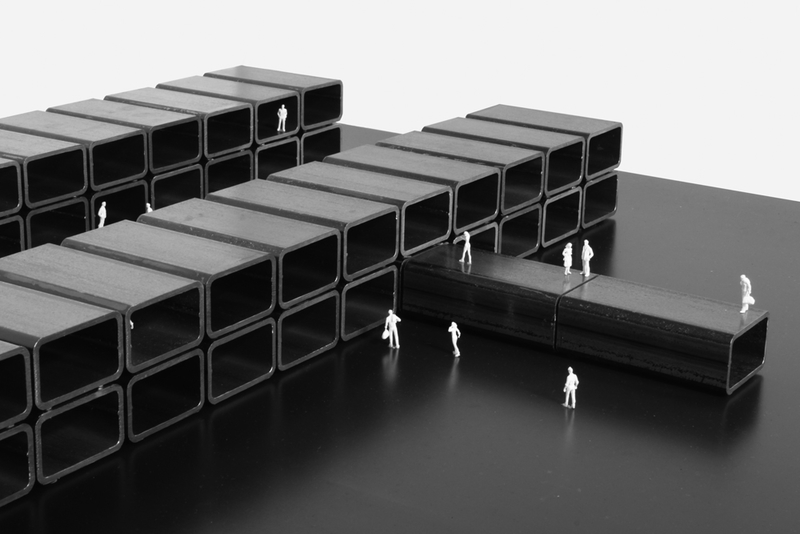

The stacked concrete modules comprising the student housing complex in Sant Cugat del Vallès make a perfect example of prefabricated building. For not only the supporting reinforced concrete structure was produced in a factory, but the façades, bathrooms and fittings were as well.

Architect: dataAE, Barcelona, HARQUITECTES, Sabadell

Location: Carrer de Pere Serra 1, Sant Cugat del Vallès, Spain

Architect: dataAE, Barcelona, HARQUITECTES, Sabadell

Location: Carrer de Pere Serra 1, Sant Cugat del Vallès, Spain

A prerequisite for participation in the design competition hosted by the Polytechnic University of Catalonia was the use of modular, prefabricated concrete systems produced by a Spanish manufacturer. The winning team from two Catalonian architecture studios took the liberty of modifying the concrete boxes, which are open on the front side, according to their own vision. For one thing, they did without the wall and floor coverings suggested by the manufacturer and simply left these surfaces raw. They also chose a size of 5 X 11.2 metres- the maximum dimensions allowed for transport by truck.

Sixty-two of these modules have been stacked in two rows, each with two storeys. In between, a long inner courtyard serves as meeting-place and forms the heart of the complex. This courtyard is flanked by pergolas of prefab concrete. On the exterior sides, climbing plants creep up a steel web, providing shelter from the sun and breaking up the repetitive perforated façade.

The individual modules measure about 40 m² and are home to one or two students. The bathroom is next to the entrance; the kitchen counter, which features open shelving, is located on the rear side of the bathroom. The rest of the space can be furnished as desired.

The advantages of modular building lie not only in the economical manufacture and short assembly time for this construction, but also in the ease of disassembly. The individual components can easily be removed and reused elsewhere. Moreover, the building meets Swiss Minergy standards, meaning a heating requirement of less than 38 KWh/m²/a. This is unusual for Spain, but was another prerequisite set by the university.

The concrete modules were made in the factory, as were the front-side façades, which were assembled as insulated reinforced steel-wall systems. While flanged steel sheeting forms the weatherproof surface of the exposed side, the sheltered pergola side features black-coated veneer plywood panels. The prefab modules were transported to the building site and attached using a reversible steel connecting system.

Project data

Client: Universitat Politècnica de Catalunya, Barcelona,

Structural engineering: DSM arquitectes, Vic

M&E: Àbac Enginyers S.L.P, Barcelona

Environmental consultant: Societat Orgànica, Barcelona

Prefabrication: Compact Habit, Cardona

Green roof: Danosa, Fontanar

An extended report about the project can be found in DETAIL 4/2015 Prefabrication.

Client: Universitat Politècnica de Catalunya, Barcelona,

Structural engineering: DSM arquitectes, Vic

M&E: Àbac Enginyers S.L.P, Barcelona

Environmental consultant: Societat Orgànica, Barcelona

Prefabrication: Compact Habit, Cardona

Green roof: Danosa, Fontanar

An extended report about the project can be found in DETAIL 4/2015 Prefabrication.