Fungal cultures finish marble wood

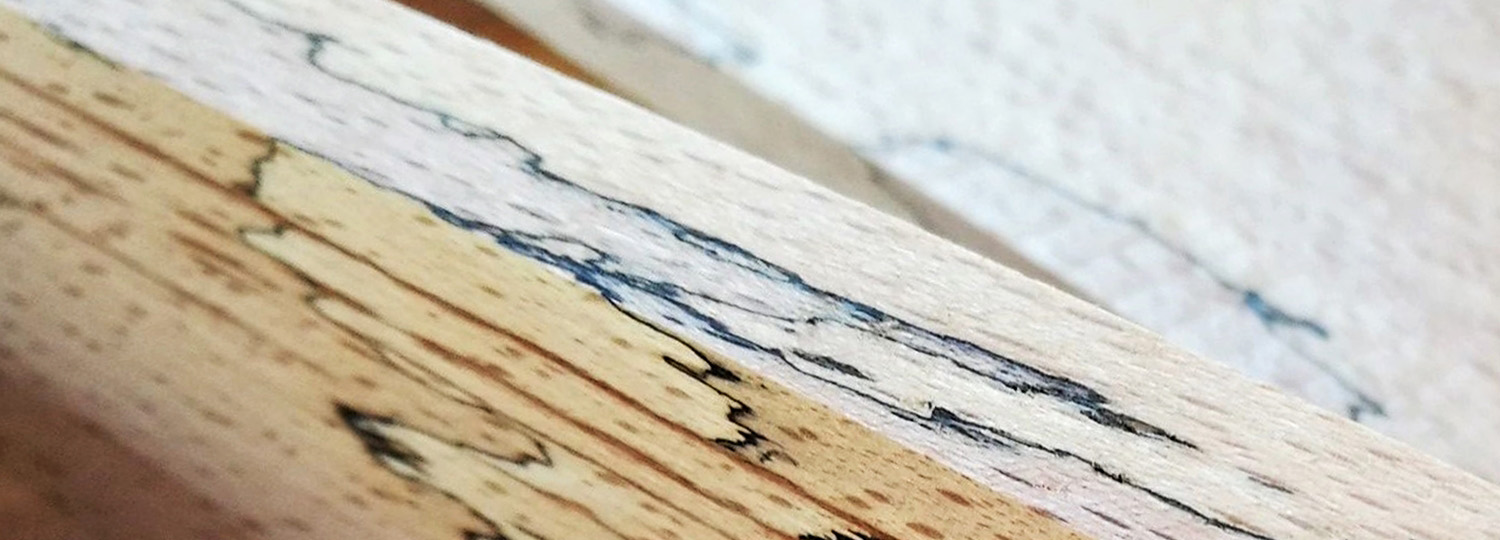

Marmorholz aus dem Labor: Je nach verwendeter Pilzart lässt sich der Verlauf der Muster im Holz steuern (Foto: Empa)

Fungi, which normally decompose tree trunks, can also transform wood into a work of art. In nature, however, the rot pathogens not only decorate the tree, they also destroy it. Scientists are now teaching the fungi in laboratories how to draw. The result is marbled wood that, for example, can be processed into furniture, parquet flooring, kitchen fronts or decorative objects.

Patterned truffle beech has been a popular material for high-quality furniture since antiquity. It is usually the result of years of decay. Only rarely is it possible – regardless of whether it was produced naturally or artificially – to obtain high-quality wood that is decorated by fungi and yet usable. Scientists from the Applied Wood Materials department have now developed a method to treat hardwoods such as beech, ash and maple with fungi cultures and to guide the special graining process in a controlled manner.

The most suitable fungal species for wood finishing were the brittle cinder and turkey tail fungi, which leave black lines pigmented with the dye melanin and at the same time fade the surrounding wood thanks to the enzyme laccase. The result is a pattern with a particularly strong contrast in the wood. Depending on the combination of fungi species used, the lines are wild and impetuous or almost geometrically precise. "The fine black lines run through the wood like battle scars. Sometimes they wind restlessly towards each other and separate small areas on the light background. In other places, the dark drawings flow calmly and quietly, marking boundaries that none of them may cross. Fungi have fought a battle for territory and resources here in the wood and have clearly separated themselves from each other with darkly pigmented lines. With these demarcation lines, the fine filaments of the fungal community not only protect their colony from other fungi, the pigment boundary also ensures that bacteria and insects stay away and the habitat retains an ideal amount of moisture," the researchers explain.

One particular advantage of the fungi used in the laboratory is that they hardly attack the wood, despite a pronounced grain through pigments, and the wood therefore retains its stability and shape. However, the fact that the process can be controlled according to the desired result is not only due to the type of rot pathogen used. The researchers have also developed a process in which the wood is ready for processing within weeks. One of the reasons for this is that the selected fungi species are found in wood with significantly less moisture. This means that the raw material after its finishing and before its processing into furniture does not have to be dried in a long, costly and energy-intensive process.

With the new technology, the finished wood can now be produced faster, more sustainably and with the desired marbling. Together with industry partner Koster Holzwelten AG, the researchers are currently working on implementing an efficient and ecologically-sustainable production method for marble wood from local beech.