Monolithic Transparency: Research and Development Centre in Dogern

The primary design feature of the new research centre of the office furniture manufacturer Sedus Stoll is a textile skin made of glass fibre fabric. Suspended in front of the façade in two layers , the skin gives the building an appearance ranging from solid structure to just about to dissolve. Special adapter profiles made of aluminium were developed for attachment. The translucent membrane furthermore has a positive influence on the total energy balance of the building.

Architects: ludloff + ludloff Architekten, Berlin

Location: Hauptstraße 4, D-79804 Dogern, Germany

Client: Sedus Stoll AG, Waldshut

Structural engineers: Sobek Ingenieure, Stuttgart

Architects: ludloff + ludloff Architekten, Berlin

Location: Hauptstraße 4, D-79804 Dogern, Germany

Client: Sedus Stoll AG, Waldshut

Structural engineers: Sobek Ingenieure, Stuttgart

Concept

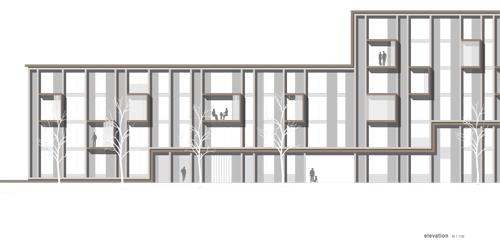

For decades, the renowned manufacturer of office furniture, Sedus Stoll, has been wanting to shift the key development area of the company from the historical location in Waldshut in the south of the Baden region of Germany, to the neighbouring town of Dogern. In 2003, the design-oriented company commissioned Sauerbruch Hutton Architekten to create a high bay warehouse in the shape of a huge colourful box. Seven years later, the structure was joined by a worthy counterpart: situated between the 30-metre-high warehouse and the rural infrastructure, the new research centre presents itself as a white, introverted monolith with a sloping roof.

For decades, the renowned manufacturer of office furniture, Sedus Stoll, has been wanting to shift the key development area of the company from the historical location in Waldshut in the south of the Baden region of Germany, to the neighbouring town of Dogern. In 2003, the design-oriented company commissioned Sauerbruch Hutton Architekten to create a high bay warehouse in the shape of a huge colourful box. Seven years later, the structure was joined by a worthy counterpart: situated between the 30-metre-high warehouse and the rural infrastructure, the new research centre presents itself as a white, introverted monolith with a sloping roof.

Textile skin

The textile skin is a major design feature. The glass fibre fabric is attached to steel tubing frames, which are up to 12 m high, using specially developed adapter profiles made of aluminium. Springs in the holding profiles offset changes in length of the construction due to temperature fluctuations, maintaining the tautness of the membrane. The translucent material provides protection from the sun and rain, is dirt-repellent and allows ideal rear ventilation. It also meets exacting aesthetic requirements: suspended in front of the façade in two layers, sun protection blinds are used to achieve varying degrees of transparency, giving the building – depending on the light conditions – an appearance ranging from solid structure to just about to dissolve.

The textile skin is a major design feature. The glass fibre fabric is attached to steel tubing frames, which are up to 12 m high, using specially developed adapter profiles made of aluminium. Springs in the holding profiles offset changes in length of the construction due to temperature fluctuations, maintaining the tautness of the membrane. The translucent material provides protection from the sun and rain, is dirt-repellent and allows ideal rear ventilation. It also meets exacting aesthetic requirements: suspended in front of the façade in two layers, sun protection blinds are used to achieve varying degrees of transparency, giving the building – depending on the light conditions – an appearance ranging from solid structure to just about to dissolve.

Rahmen Stahlrohr = Steel tubing frame

Glasfasergewebe, silikonbeschichtet = Glass fibre fabric, silicone-coated

Adapter Aluminium = Aluminium adapter

Klemmprofil = Clamping profile

Glasfasergewebe, silikonbeschichtet = Glass fibre fabric, silicone-coated

Adapter Aluminium = Aluminium adapter

Klemmprofil = Clamping profile

The waste heat of a hydropulser in the workshop is used for hot water generation in the research centre. A bivalent water heater tank allows the hot thermal energy gained to be used for various purposes including heating service water, bringing water for showering to the required temperature, as well as the heating system. A branch from the well water return pipe is used to provide water for flushing the toilets and for irrigation of the outdoor green areas. Rainwater run-off from the roof surfaces seeps into the ground via a ditch . All artificial light sources are made of energy-optimised components and connected to a daylight-dependent control system.

All materials used were checked in terms of their overall energy balance and recyclability: a sustainable building in every sense has been created. The structure made of concrete and wood, and all the finishing constructions with integration of the building services engineering equipment, were designed for energy-optimised operation, including deconstruction and low-pollutant disposal.

All materials used were checked in terms of their overall energy balance and recyclability: a sustainable building in every sense has been created. The structure made of concrete and wood, and all the finishing constructions with integration of the building services engineering equipment, were designed for energy-optimised operation, including deconstruction and low-pollutant disposal.

Energy concept

Text: ludloff + ludloff Architekten

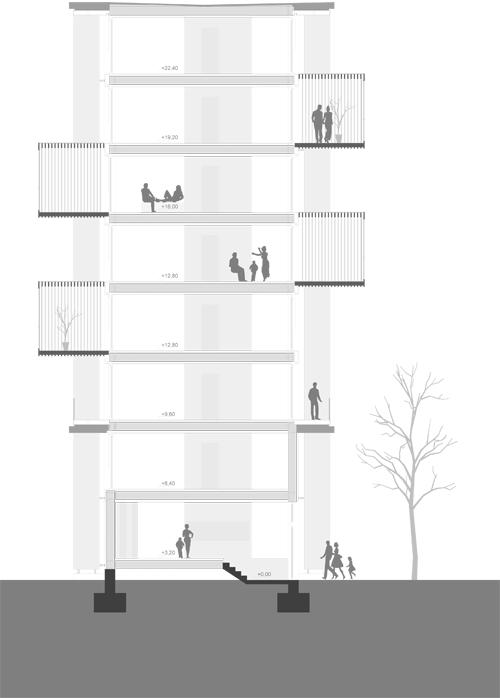

Temperature control of the office area is realised by means of a flush-mounted heating/cooling ceiling. This completely meets the heating requirements of these rooms, which are low due to the thermal optimisation of the compact volume. The exterior glass fabric envelope protects the building from overheating in summer, and sun protection blinds made of the same material are provided for the window areas. An intentionally large volume of air in the area of the open-plan offices allows compensation of local internal thermal loads and temperature fluctuations.

The meeting rooms situated in the inner area of the first floor are equipped with an additional mechanical ventilation system. Heat recovered from waste air is used for pre-conditioning the supply air in winter. The location of the building in the immediate vicinity of the River Rhine, means that cooling requirements can be fully met with a heat exchanger and use of well water, without having to produce cold thermal energy mechanically. A conventional heating system with steel tube radiators is used for heating the workshop and experimental areas on the ground floor. Customary circulating air coolers (also utilising cool well water) are adequate in the workshop area due to limited and sporadic running periods.

Text: ludloff + ludloff Architekten

Temperature control of the office area is realised by means of a flush-mounted heating/cooling ceiling. This completely meets the heating requirements of these rooms, which are low due to the thermal optimisation of the compact volume. The exterior glass fabric envelope protects the building from overheating in summer, and sun protection blinds made of the same material are provided for the window areas. An intentionally large volume of air in the area of the open-plan offices allows compensation of local internal thermal loads and temperature fluctuations.

The meeting rooms situated in the inner area of the first floor are equipped with an additional mechanical ventilation system. Heat recovered from waste air is used for pre-conditioning the supply air in winter. The location of the building in the immediate vicinity of the River Rhine, means that cooling requirements can be fully met with a heat exchanger and use of well water, without having to produce cold thermal energy mechanically. A conventional heating system with steel tube radiators is used for heating the workshop and experimental areas on the ground floor. Customary circulating air coolers (also utilising cool well water) are adequate in the workshop area due to limited and sporadic running periods.

A detailed documentation of the project in print can be found in DETAIL 1+2/2013 on Transparency.